Raising America’s Turkeys

Raising turkeys is around-the-clock work. In 2022, more than 210 million turkeys were raised on about 2,500 farms across the United States, with the majority being family farms. NTF is working to amplify the hard work done by the men and women across the turkey industry to support America’s robust food supply. Read on to learn more about raising turkeys and the turkey production process in the United States.

Raising Birds to Maturity

Broad-breasted White is the most commonly domesticated breed of turkey. This breed is raised to produce more breast meat and meatier thighs and is recognizable by their white feathers. Other variations, such as heritage turkeys, are also bred in niche markets.

Turkey eggs are tan with brown specks and are larger than chicken eggs. The incubation period to hatch a turkey egg is 28 days. Once hatched, a baby turkey is called a poult and is tan and brown. Male turkeys are called toms, while female turkeys are called hens.

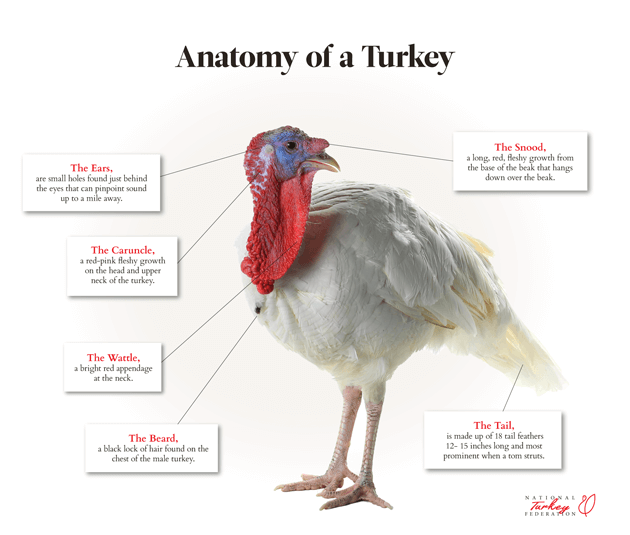

Do you know the anatomy of an adult turkey?

Fun fact: Broad-breasted turkeys are bred with white feathers, so they leave no unsightly pigment spots under the skin when plucked.

How Turkeys Are Raised

American farmers are raising turkeys in scientifically designed, environmentally controlled barns that provide maximum protection from predators, disease and weather extremes. They are fed a balanced diet of corn and soybean meal mixed with a supplement of vitamins and minerals. Genetic improvements, better feed formulation and modern management practices are responsible for the size of turkeys produced today.

On average, it takes 75-80 pounds of feed to raise a 38-pound tom turkey. Feed ingredients account for roughly two-thirds of the cost of raising a turkey. Modern production methods have shortened the time it takes for turkeys to reach maturity. A hen usually takes 14 weeks and weighs 15.5 pounds when processed, but a tom takes roughly 18 weeks to reach a market weight of 38 pounds. Hens are typically processed and sold as whole birds, while toms are often further processed into products such as cutlets, tenderloins, turkey sausage, turkey franks and turkey deli meats.

To maintain production continuity, laying hens are artificially inseminated in a controlled environment. During a 25-week laying cycle, a hen normally lays 80-100 eggs. At the end of this cycle, the hen is “spent” and usually processed. Some breeders choose to molt the hen (allow a resting period) before another production cycle. This process takes 90 days; however, the second laying cycle will produce slightly fewer eggs (75-80).

Get a behind the scenes glimpse at a turkey farm and processing plant led by animal welfare expert Dr. Temple Grandin, professor of animal science at Colorado State University.

Dedication to Animal Health

To prevent disease when raising turkeys, turkey growers rely on vaccination, biosecurity against outside contamination, good hygiene, best management practices and placing newly hatched poults certified free of specific infections. However, just like humans, animals sometimes get sick and need further medical attention. NTF and the turkey industry are working together to identify and address some of the biggest health challenges facing turkey production today.

Questions about avian influenza? Click here to learn more, including the turkey industry’s response to animal health challenges and sustained commitment to biosecurity.

Antibiotics have been safely used in animal agriculture for half a century to treat and control disease in animals and improve the animal’s overall health. Advancements in genetics, veterinary management and animal disease research have led to improved animal health and less reliance on antibiotics. In addition, the turkey industry supports alternatives and new mitigation strategies to support challenges producers face.

Environmentally Conscious

Turkey growers not only care for the animals they raise, but they are also dedicated stewards of the land and take precautions to ensure their farms’ longevity through sustainable agriculture practices. Many turkey farms have been active for generations and are passed down through the family. Sustainability is tantamount to the success of the growing operation and is becoming a standard across the turkey industry.